Products

-

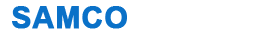

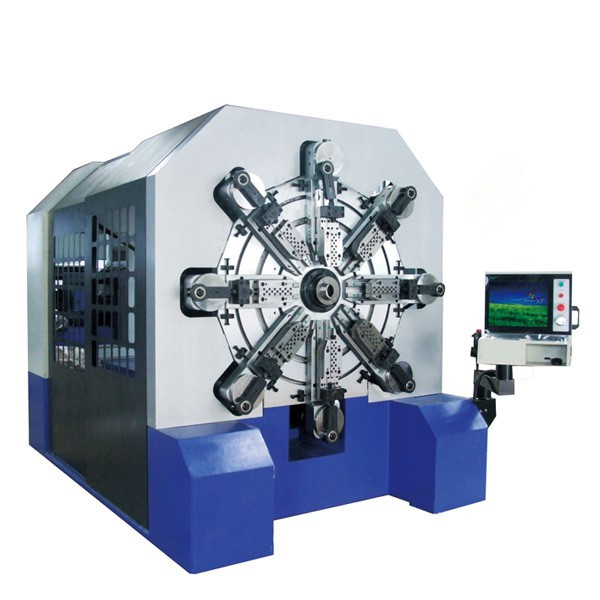

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

SAMCO supply spring forming machine, CNC8335 is a 3 axis CNC spring machine, can make compression spring, tension spring, torsion spring, coiling spring and wire forms and etc

Application of the spring

In the early 1970's, CNC wire benders did not exist. Today, the technological advances have totally changed the industry. In the 70's the machines were all mechanical. Secondary departments were huge rooms filled with women working kick presses making all those extra loops and bends. Now we have machines that put all those extra bends and loops on the part all in one operation. In most spring making shops the secondary department has shrunk or totally disappeared. The kick press? I'll bet a lot of youngsters in the industry have no idea what it is. Here we will group the machinery in three areas. • Compression Springs • Wire Forms • Manual Operations In the compression springs area we have spring coilers, lathe coilers and spring grinders to look at. In the wire forms area there is an incredible array of machinery. There is everything from 2-D and 3-D benders on up to 12 axis radial type formers for wire forms and torsion springs. The manual operations area will cover all the hand type operations using hand winders for torsion springs, to secondary loopers, and manual wire bending equipment. For simplicity sake we add stress relieve ovens in this area. This includes both conveyor type and box type.