Products

-

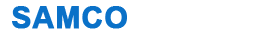

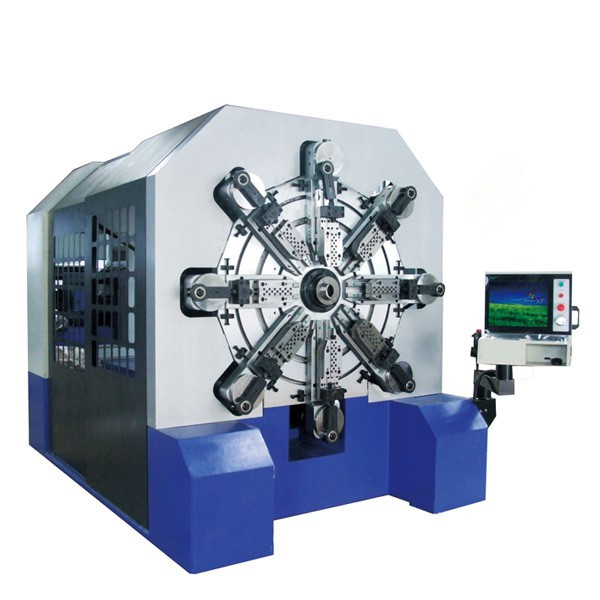

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

SAMCO supply spring forming machine, CNC8335 is a 3 axis CNC spring machine, can make compression spring, tension spring, torsion spring, coiling spring and wire forms and etc

About Spring and Wire Forming Machines

Spring and wire forming machines are used to form wire into springs and other wire shapes. Categories include manual spring coilers and automated spring coiling machinery, manual and automatic spring detangles, and in-line process control and heat treatment equipment for wire forming. Spring and wire forming machinery also includes wire cutters, wire benders, wire grinders, wire strengtheners, four-slide wire formers, and CNC wire forming equipment. In addition to manual and automatic equipment, semi-automatic machinery is available. Often, spring and wire forming machines are integrated with an assembly line to meet application-specific requirements such as feed rate, spring design and tolerance. Feed rate is the speed at which materials are fed to spring and wire forming machines. In many systems, wire is fed to one or more points from a single coiling system. Spring and wire forming machines use winders to pull a wire and coil it into a spring shape. Some systems incorporate or are designed for use with grinders and wheels, finishing equipment, testing equipment, and tooling stock. Spring finishing includes plating, passivity, coloring and coating. Most spring forming equipment is designed to fabricate springs from spring steel, music wire, and stainless steel. Spring steel is a standard, industrial-grade steel that is designed specifically for spring manufacturing. Music wire is another common and relatively inexpensive high-carbon steel alloy used for spring making. Stainless steel is a common spring material with good corrosion resistance. Spring and wire forming machines that are designed for use with exotic metals and plastics are also available. Spring and wire forming machines may differ in terms of supported spring designs and tolerance. Typically, spring making equipment is used to fabricate Belleville washer springs, compression springs, conical springs, constant-force springs, die springs, disc springs, extension springs, and flat springs. Spring and wire forming machines for leaf springs, power springs, torsion springs, valve springs, variable-pitch springs, wire forms, and wire shapes are also available. Examples of wire products made with wire formers include anchors, bails, benders, brackets, clamps, frames, grilles, handles, hooks and rings. For both springs and wire forms, spring and wire forming equipment may meet or exceed published standards for the squareness of ground ends and free lengths.