Products

-

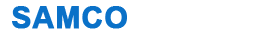

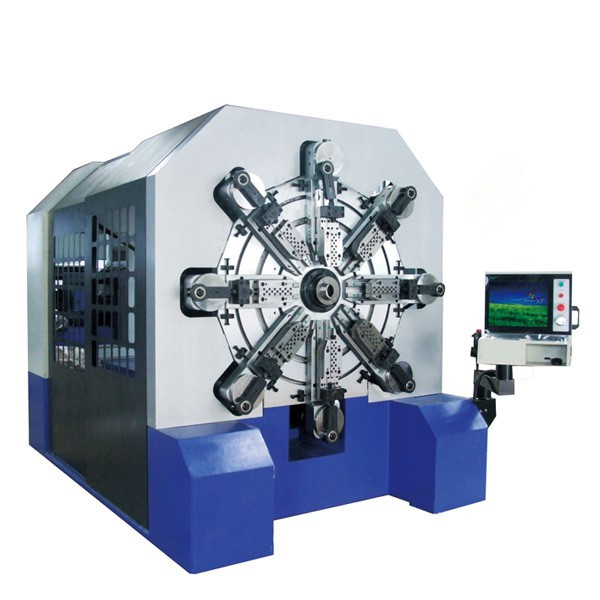

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

SAMCO supply spring forming machine, CNC8335 is a 3 axis CNC spring machine, can make compression spring, tension spring, torsion spring, coiling spring and wire forms and etc

CNC Technology

With skilled craftsmen dwindling in numbers, CNC machines quickly becomes the technology of choice for large and small woodwork shops. Computer Numerical Control (CNC) is for operating machine tools with computer programmed instructions. They are keyed into a computer and sent to automatic devices; typically rotary servo motors driving ball screws, or other mechanisms such as a rack and pinion, or timing belt drives. CNC systems are used to execute a series of precise movements and operations. Recent developments such as automatic part measurement and parametric scaling of parts, allow an operator to upload a set of instructions. It also lets the computer calculate the exact cut path according to predefined parameters. The control of these machines range from simple linear positioning.