Products

-

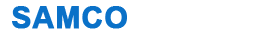

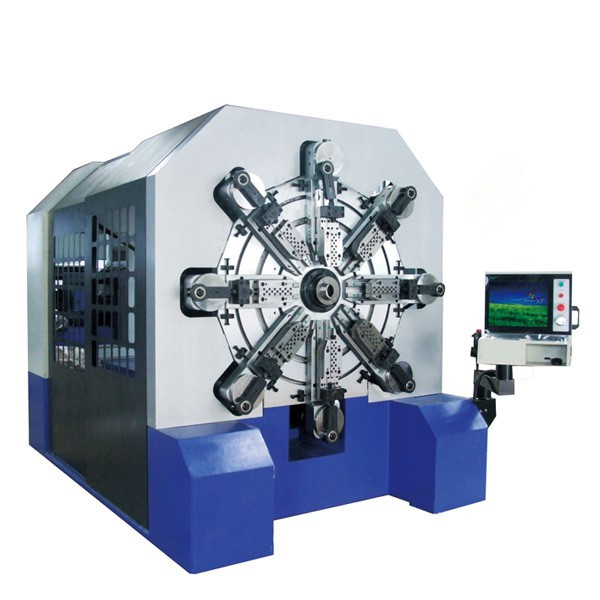

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

SAMCO supply spring forming machine, CNC8335 is a 3 axis CNC spring machine, can make compression spring, tension spring, torsion spring, coiling spring and wire forms and etc

Torsion Springs

Helical springs used to apply a torque or store rotational energy are commonly referred to as torsion springs. The two most common types are single and double-bodied springs. Torsion springs are found in clothespins, window shades, counterbalance mechanisms, ratchets, hinges and various other machine components. They are also used as couplings between concentric shafts such as in a motor pump assembly. Torsion springs are generally mounted around a shaft or arbor, and must be supported at three or more points.

Torsion springs are stressed in bending. If possible, a torsion spring should always be loaded in a direction that causes the body diameter to decrease. The residual forming stresses are favorable in this direction, but unfavorable when the spring is loaded in a direction that increases body diameter. Unless there are unfavorable residual stresses in the end bends, spring makers normally heat-treat these springs at a low temperature to stabilize the end positions rather than fully stress-relieve them. If the direction of loading tends to increase body diameter, the spring maker should be advised to stress-relieve the springs.