Products

-

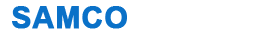

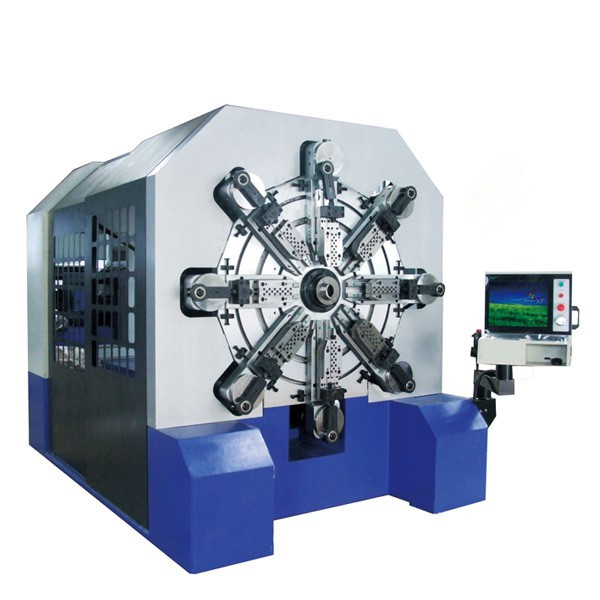

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

SAMCO supply spring forming machine, CNC8335 is a 3 axis CNC spring machine, can make compression spring, tension spring, torsion spring, coiling spring and wire forms and etc

Extension Springs

While many applications require springs that dampen force and perform a pushing action, others require springs that oppose extension by pulling themselves back together. Extension springs, also called tensile springs, are found in many applications, such as a common household stapler, snow plows, garage doors and various types of spring tensioning devices. Extension springs are typically made with initial tension, which forces the coils to press against each other in the unloaded position. Extension springs are typically installed with an initial tension that stretches the spring until the coils are close to separating. After the initial tension has been applied, the extension spring deflects only if it receives a load greater than the initial tension. Extension springs have hooks on their ends to attached them to the application. Various hook styles and configurations are available depending on the particular application. Helical extension springs do not normally have set removed. Furthermore, unlike compression springs, extension springs do not have a solid stop to prevent overloading. For these reasons, design stresses are generally lower for extension than compression springs. A special type of extension spring, known as a drawbar spring, has a solid stop. It is essentially a compression spring with special hooks.