Products

-

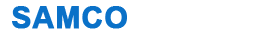

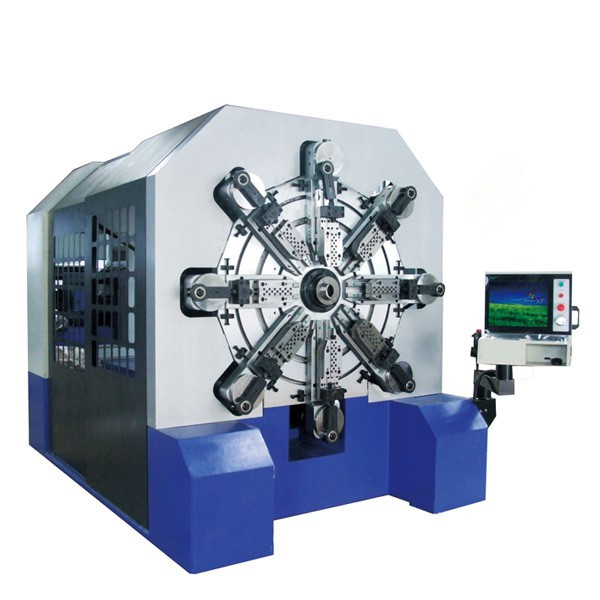

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

SAMCO supply spring forming machine, CNC8335 is a 3 axis CNC spring machine, can make compression spring, tension spring, torsion spring, coiling spring and wire forms and etc

Compression Springs

Helical compression springs are designed and used to resist applied compressive forces or to store energy in the push mode. Compression springs are the most common spring configuration and are found in many applications such as automotive, aerospace and consumer goods. The most widely used form of compression spring is the straight cylindrical spring made from round wire; however, shaped wire may be used, such as square or rectangular. Many other forms are produced. Conical, barrel, hourglass or straight cylindrical with or without variable spacing between coils are available. Such configurations are used to reduce solid height, buckling and surging, or to produce nonlinear load deflection characteristics. Energy storage is greater for round wire compression springs than for rectangular wire compression springs and can be increased by nesting. Rectangular wire is used to reduce solid height or increase the space efficiency of the design. Most die springs are made from rectangular wire for this reason. It should also be noted that most compression springs have closed and ground ends, although there are other end configurations available depending on the particular application. In applications where space is limited and particularly where solid height is restricted, springs designed from rectangular wire are often used. These springs are commonly referred to as die springs. Die springs store more energy in a smaller space than equivalent round-wire springs. Even though stress distribution around the rectangular cross section is not as uniform as the round wire section, the energy storage capacity is higher because more material can be incorporated into the allocated space.