Products

-

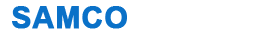

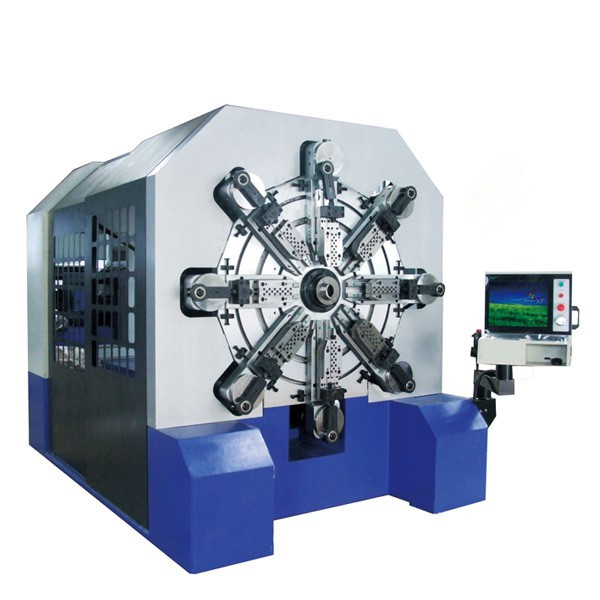

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

SAMCO supply spring forming machine, CNC8335 is a 3 axis CNC spring machine, can make compression spring, tension spring, torsion spring, coiling spring and wire forms and etc

The Wire Types Used by Spring and Wire Formers

What is the best type of wire to use for a spring? There is a wide variety of spring steel to choose from. What does the designer or spring manufacturer look at when determining his choice? Determining factors should be the strength (load requirement) and expected life of the spring. What type of environment will the spring be used in? Will there be extreme heat or cold, wet or dry, or other influences? After all, springs can be used for a variety of items... ...from the art of a fancy shoe rack to highly precision medical items like dental forms. Other factors would be the manufacturing processes available and, of course, the cost of the raw material. To help determine these items there should be a close working relationship, right from the start, between the spring maker and the customer. This ensures the best design and the best material choice is used. Without this initial cooperation unnecessary cost is added to the product in more cases than not. And also the spring machine is very important,such as versatile spring is usually used for making wire molds,there is also compression spring machine to make oil seal spring,compression spring, The choices of material from high carbon steels, alloy steels, stainless steel, copper alloy types and others are many. Most springs are made from high carbon steels ranging from 0.50% to 1.20%. All of these factors need to be considered in choosing the correct steel. Consideration should also be given to other types of materials than the standard high carbon steel. This may save some cost. The terminology used in discussing raw material for the spring forming industry contains a lot of different words for the same things. A lot depends on the area of the industry the spring maker is supplying. Do they talk in gauge or size? If you need a little help on some of the terms being used, please go to our page on terms. Speaking of wire size... When considering the right material not only the size needs to be decided but also the shape. Special shaped material can help a lot in giving the spring more strength and life. For example, oval shaped material has greatly aided design considerations for engine valve springs. Shapes and sizes of spring steel can vary greatly from round, oval, flat, square, rectangle, and many other types as required. If you are having a tough time getting the proper material to meet your needs you should check out the shaped types. It is good to know how the most common spring materials are used and there physical properties. Our page on spring steel types will provide this information for you. After deciding on the type needed you can check our listing of the various distributors and manufacturers of wire to find the cost and availability. Unless you are buying a large volume of the same material you will most likely be purchasing from a distributor. Distributors buy their material from many different suppliers. They can offer you the widest selection of choices and prices. If you know exactly what you need and are in need of a very large quantity, say several thousand pounds, then you might want to try a direct purchase from a manufacturer. Beware, they are a little harder to deal with, and the lead time may be way out there!