Products

-

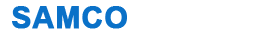

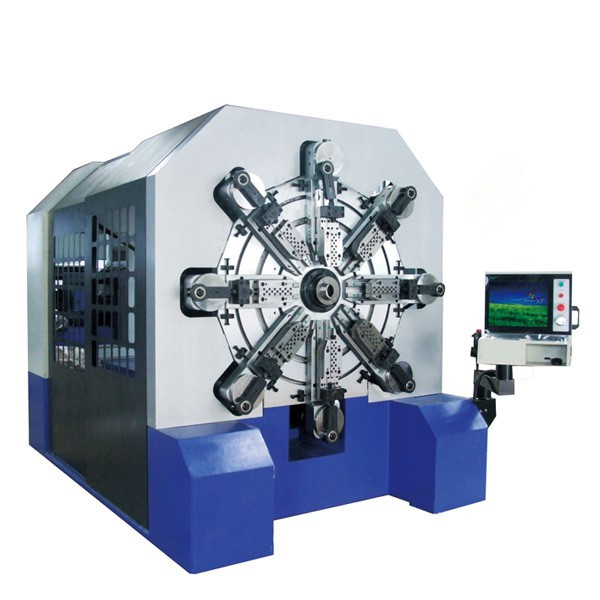

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

CNC1280 CNC Multi-Axes Wire Bender Machine

Description:

1. Without cam and rocker design (debugging machine speed is faster above 50% than traditional with CAM spring machine, and production speed is faster over 100% than their highest speed, precise positioning, stable operation).

2. With the advantages of the traditional 8 station machine, and both the 1 groups of free hand, can be up and down, left and right, free play (producing complicated springs, more easy, more efficient and more accurate.)

3. The whole rolling guideway, keeping accuracy all the way.

4. No collision machine and fever, composite tool to complete all the processes, cutting tool loss low.

5. Intelligent module, automatic detection and alarm.

6. Windows window operation, Chinese and English interface show, easy operation.

Product Range:

Unique camless and no rocker arm design, by multiple sets of servo motor independent control, you can produce a variety of special shaped springs, pressure springs, double torsion springs, battery springs, flat springs (clock type flat springs) and all kinds of wire forming, etc. Precision and accuracy, debugging machine quickly, stability and reliability.

| Model: | CNC1280 |

| Wire Diameter | 3.0-8.0mm |

| Max. Wire Feed Instruction Value | 10000.00mm |

| Min. Wire Feed Instruction Value | 0.01mm |

| Max. Wire Feed Speed | 80m/min |

| Max. Wire Feed Length | Unlimited |

| Axles Number | 12 |

| Total Output Power of Servo Motor | 57.0KW |

| Input Voltage | 380v |

| Software | Industrial Grade Computer |

| Program Data Storage | More than 2000pcs |

| Pneumatic System(Air pressure) | 5-6KG/cm |

| Pneumatic System(Probe) | 3 |

| Depth | 3150mm |

| Width | 2500mm |

| Height | 2500mm |

| Machine Weight | 5500KG |