Products

-

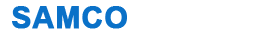

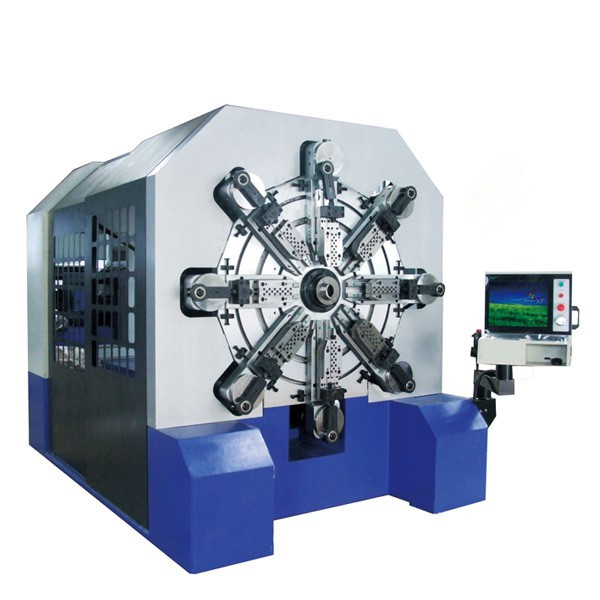

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

CNC8350 coiling spring machine

Description:

- 1. CNC8350 coiling spring machine consists of cam axis, wire feeding axis, rotation core and rolling axis. The mechanical part has eight sets of sliding blocks. The winch and cam rotation have three mechanical part has eight sets of sliding blocks. The winch and cam rotation have three mechanical action types: extruding, punching and molding.

- 2. The computerized cam rotation system can be set from 0.1-359.9°, every two wire feeding wheels constitutes of one group, totally three groups.

- 3. CNC8350 universal spring machine is equipped with four-axes spring machine controller. The controller system can save 1000 material numbers. Axis location, feeding data, production speed and production output are displayed on the screen. The program data can be set and changed easily.

- 4. The spring machine rotation core system is installed on the axis. The axis can rotate leftwards and rightwards. The rolling axis is installed on the sliding house. The cam drives it rotate 360°, also can control direction action or designated moves back and forth.

5. English interface, easy operation, accurate positioning, according to the fluorescent screen work, can amend diameter angle of springs anytime.

6. Wireless, wire breakage and winding automatically stops design and wire frame automatic acceleration function, make production more easily and effectively.

7. With precision detecting and tracking device, substandard products can automatically stop. Mechanical parts automatic supply lubricating oil design, ensure equipment long time running.

- 8. Optional accessories: Cutting tools, rolling axis, safety door.

Technical Paremeters for Coiling Spring Machine CNC8350:

Wire Diameter: φ1.0~5.0mm Maximum Outside Diameter: φ135mm Maximum Wire Feed Speed: 70m/min Wire Feed Instruction Value: ±0.01~±9999.99 Cam Instruction Value:

Cam Rotation Speed:

±0.1°~±359.9°

0~60RPM

Cam Servo Motor: 7.0KW Wire Feed Servo Motor: 7.0KW Core-switching Axis Servo Motor: 1.5KW Power Supply: 3-Phase 380V Dimensions(L*D*H): 1900*1400*2200mm Machine Weight: 2500KG