Products

-

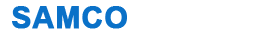

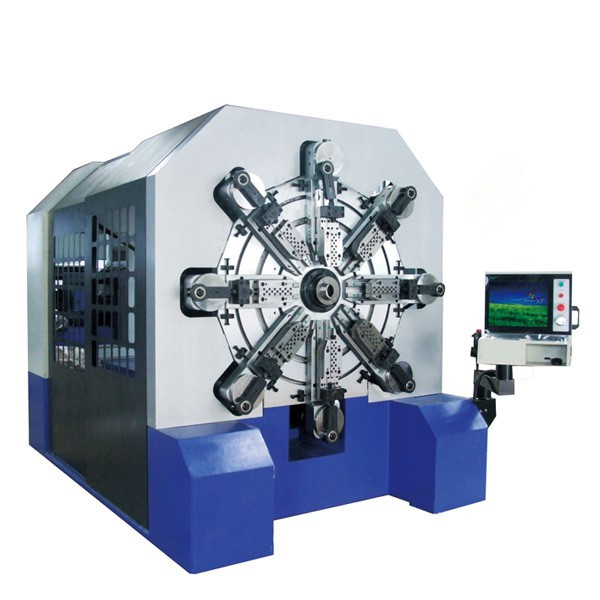

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

SAMCO supply spring forming machine, CNC8335 is a 3 axis CNC spring machine, can make compression spring, tension spring, torsion spring, coiling spring and wire forms and etc

How to make CNC spring machine high efficiency running in daily production

To make CNC spring machine high efficiency running in daily production, we can do this:

1. Before your starting production, please check all the fasteners which is removed during debugging machine. After starting, operating strictly according to use steps after, to avoid loose, drop, shifting, occur ram impact machine phenomenon, lead to machine damage.

2. When spring machine is in a relatively long downtime, it's better to loosen wire feeding wheel as far as possible. Because long time pressure will lead to bearing damage and mild deformation of wire feeding wheel. making the precision of the springs unstable in future production.

3. No touch the spring machine panel when machine is running.

4. Must control the direction of spring drops, to avoid stuck the knife holder, occur ram impact machine phenomenon.

5. When spring product is unusual, must stop first, then adjust and modify to avoid accidents.