Products

-

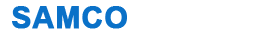

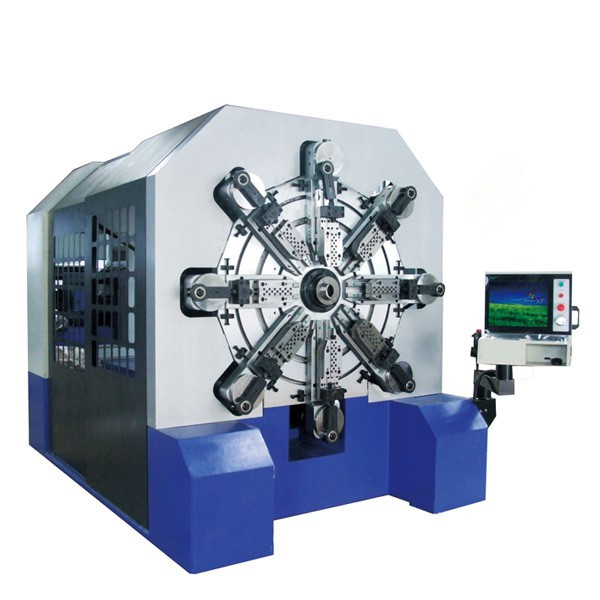

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

SAMCO supply spring forming machine, CNC8335 is a 3 axis CNC spring machine, can make compression spring, tension spring, torsion spring, coiling spring and wire forms and etc

The common defects and prevention measures of spring quenching

Common defect of spring quenching, let’s introduce some prevention measures:

Defect I: Decarburization( lower use life ); Measure:1. Using a salt bath furnace or atmosphere furnace heating;

2. Using rapid heating process.

Defect II: Lack of hardness after quenching, the number of non-martensite is too large, the core appear ferrite; Measure:

1. Choose good harden ability materials;

2. Improve cooling capacity of the quenching coolant;

3. The temperature of spring enter into the coolant should be controlled above Ar3

4. Appropriate improve quenching heating temperature.

Defect III. Overheating (Brittleness increases);Measure

1. Strictly control heating temperature of forming and quenching;

2. Strengthen the quenching in metallographic examination.

Defect IV. Cracking(Brittleness increases, lower use life severely); Measure:

1. Control quenching heating temperature.

2. When quenching and cooling to 250-300°, then take out and cooling in the air;

3.Tempering timely.