Products

-

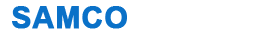

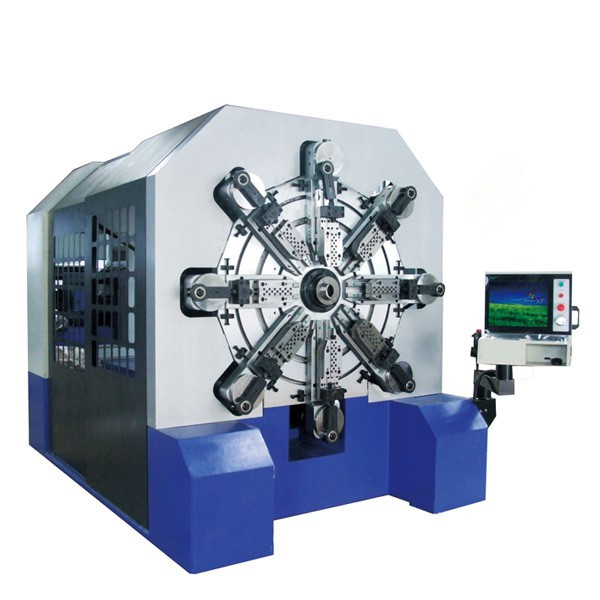

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

SAMCO supply spring forming machine, CNC8335 is a 3 axis CNC spring machine, can make compression spring, tension spring, torsion spring, coiling spring and wire forms and etc

Springs applied among industries

Compression spring Compression spring are widely used computer, electron, home appliances, camera, instrument, motorcycle, automobile, railway, electric power station, engineering machinery, mining machinery, construction machinery, elevator and other industry. d (wire diameter): the diameter of wire used as material for spring. S (shaft): the maximum diameter of spring shaft in industrial applications. Di (internal diameter): Internal diameter of a spring can be calculated by subtracting the doubled wire diameter from the external diameter of a spring. De (external diameter): External diameter of a spring can be calculated by adding the doubled wire diameter to the internal diameter of a spring. H (hole): This is the minimum diameter of the hole in which spring can work. P (pitch): Average distance between two subsequent active coils of a spring. Ln (block length): Maximal length of a spring after total blocking. This parameter is shown in the picture on right. L0 (free length): Free length of compression springs is measured in its uncompressed state after previous one time blocking. Nr of coils: This is a total number of coils in a spring - in the picture above it is equal to six. To calculate number of active coils substract two terminating coils from total number of coils. R (spring rate): This parameter determines spring's resistance, while it is working. It is measured in 1 DaN/mm = 10 N/mm. L1 & F1 (length at force F): Force F1 at length L1 can be calculated from equation : F1 = (L0-L1) Extension springs These tension spring are widely used in computer, electron, home appliances, camera, instrument, motorcycle, automobile and other industry. d (wire diameter): This parameter describes the diameter of wire used as material for spring. De (external diameter): External diameter of a spring concerns both hooks and coils. H (Hole): This is minimum diameter of hole in which spring can work. Ln (Maximum length): Maximum acceptable extension length for a spring. It is also the maximum extension for static applications. Fn (Maximal force): Maximal acceptable force which can operate on a spring. It is also the maximum force for static applications. L0 (free length): Free length is measured in spring's free state. Nr of coils: This is a total number of coils in a spring - in the picture above it is equal to six. R (Spring rate): This parameter determines spring's resistance, while it is working. It is measured in 1 DaN/mm = 10 N/mm. L1 & F1 (length under charge F): The charge F1 at length L1 can be calculated using the equation : F1 = Fn - R(Ln-L1). Equation derived from the previous for calculating L1 = Ln - (Fn-F1)/R. Hooks: Extension springs with german hooks are produced in two versions: with hook positions of 0 degrees and 90 degrees as shown in the picture above. Wire Forms wire forms is used in switches, camera, automobiles component, switchgear, typewriters and other industrial applications. Torsion springs torsion spring are widely used in computer, electron, home appliances, camera, instrument, motorcycle, automobile and other industry. d (wire diameter): the diameter of wire used as material for spring. Dd (Shaft): maximal diameter of spring shaft in industrial applications. Di (internal diameter): Internal diameter of a spring. It can be calculated by subtracting the wire diameter multiplied by 2 from the external diameter of a spring. Internal diameter in torsion springs decreases while the spring is working even up to shaft diameter. De (external diameter): External diameter of a spring. It can be calculated by adding the wire diameter multiplied by 2 to the internal diameter of a spring. External diameter in torsion springs decrease while the spring is working. L0 (Free Length): WARNING: Free Length decrease while spring is working. Ls (Leg Length): It is the distance from the center axis of the coil body to the end of the torsion springs' leg. An (Maximum angle): Maximum acceptable rotation angle for the spring in degrees. Fn (Maximum force): Maximum acceptable force that can operate at the end of torsion springs' leg. Mn (Maximum torque): Maximum acceptable torque (Newton * mm). R (Spring rate): This parameter determines spring's resistance, while it is working. It is measured in Newton * mm / degree. A1 & F1 & M1: (angle at torque or force) The following equation calculates the angle as a function of the torque: A1 = M1/R. In order to calculate the torque from the force, we use this equation: M = F*Ls Leg position There are 4 types of torsion springs' leg positions: 0, 90 ,180 or 270 degrees (see picture above) Helix direction: A right-hand-wound spring loads in a counter-clockwise direction. A left-hand-wound spring loads in a clockwise direction. Both types are available in all sizes. Conical Springs (wire diameter): the diameter of wire used as material for spring. S (shaft): s the maximum diameter of spring shaft in industrial applications. ve) De (Larger External Diameter): External diameter at large end of the spring. Ds (Smaller External Diameter): External diameter at small end of the spring. H (hole): This is the minimum diameter of the hole in which spring can work. Ln (Block): Maximal length of a spring after total blocking. For most conical springs this value equals double wire diameter. L0 (free length): Free length of compression springs is measured in its uncompressed state after previous one time blocking. R (spring rate): This parameter determines spring's resistance, while it is working. It is measured in 1 DaN/mm = 10 N/mm. L1 & F1 (length at force F): Force F1 at length L1 can be calculated from equation : F1 = (L0-L1) * R. Equation derrived from previous for calculating L1 : L1 = L0 - F1/R. Spiral Spring spiral springs is used in D.C. motors, alternators, drill presses, vertical mill, springs balance etc.