Products

-

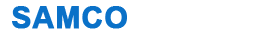

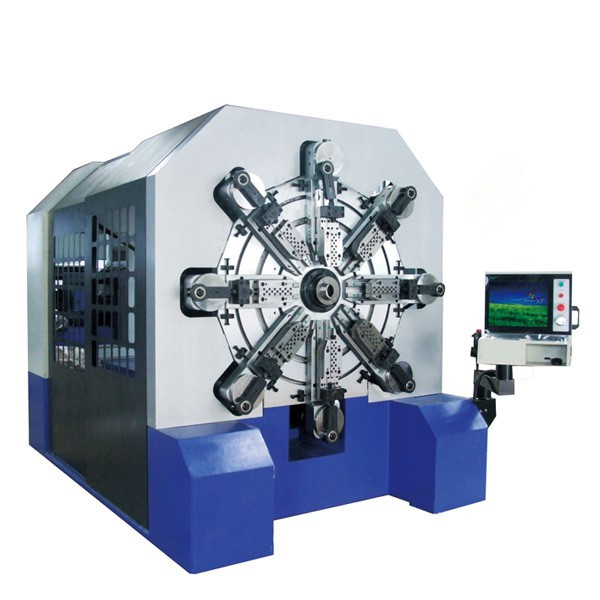

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

SAMCO supply spring forming machine, CNC8335 is a 3 axis CNC spring machine, can make compression spring, tension spring, torsion spring, coiling spring and wire forms and etc

The reasons for spring abnormal fracture

The reasons for spring abnormal fracture: Spring is the most important basic spare parts in mechanical products.It has many problems,for example(divided by shape): coil spring, spring plate (sheet), disc springs, ring springs, flat (truncated cone) scroll spring, etc.; by carrying characteristics: compression, tension, torsion spring .

The stress which spring has to withstand includes: bending stress, torsional stress, tension and compression stress and combined stress.

Spring failure modes are: fracture, deformation, relaxation, wear and tear. Most main analysis of the fracture and deformation (relaxation).

1. Fatigue fracture: spring fracture under cyclic loading.

2. Stress Corrosion Cracking: the cause of spring breakage under tensile stress and corrosive medium together.

3. Corrosion fatigue fracture: fracture of the spring under the combined effect of cyclic loads and corrosive media.

4. Hydrogen embrittlement, cadmium crisp, black brittle: in the spring material brittle fracture caused by high impurity content.

5. Wear: wear is divided into: abrasive, fatigue and corrosion and wear fracture

6. Brittle fracture: the spring break substantially belongs to brittle fracture. Only be possible when a higher operating temperature, the ductile fracture.

In engineering fatigue fracture, stress corrosion cracking and hydrogen embrittlement fracture is called brittle fracture .

The stress which spring has to withstand includes: bending stress, torsional stress, tension and compression stress and combined stress.

Spring failure modes are: fracture, deformation, relaxation, wear and tear. Most main analysis of the fracture and deformation (relaxation).

1. Fatigue fracture: spring fracture under cyclic loading.

2. Stress Corrosion Cracking: the cause of spring breakage under tensile stress and corrosive medium together.

3. Corrosion fatigue fracture: fracture of the spring under the combined effect of cyclic loads and corrosive media.

4. Hydrogen embrittlement, cadmium crisp, black brittle: in the spring material brittle fracture caused by high impurity content.

5. Wear: wear is divided into: abrasive, fatigue and corrosion and wear fracture

6. Brittle fracture: the spring break substantially belongs to brittle fracture. Only be possible when a higher operating temperature, the ductile fracture.

In engineering fatigue fracture, stress corrosion cracking and hydrogen embrittlement fracture is called brittle fracture .