Products

-

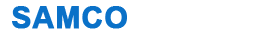

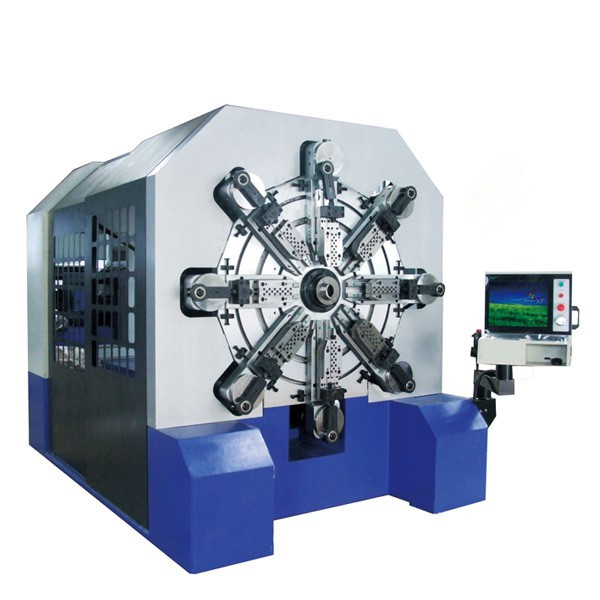

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

SAMCO supply spring forming machine, CNC8335 is a 3 axis CNC spring machine, can make compression spring, tension spring, torsion spring, coiling spring and wire forms and etc

Dvelopment of Spring Processing Technology

At present, the mechanical spring machine, spring processing equipment and processing lines go toward the numerical control (NC) and computer-controlled (CNC). The processing technology is developing with the changes of the spring material and shape.

1) Changing the spring outside diameter, pitch and diameter Suspension spring to achieve without molding processing. We usually use tapered steel bar winding working on CNC lathe machine since the development of the three transformers springs, but the yield and price are not good.

Now we get the tapered shape by through coiling spring machine in heated state and control the roll speed and pulling force, and use the waste heat to quench it.

2) Stable spring rod formed by low carbon boron-rolled steel welding.

3) Lever 45 steel with high purity, the high hardness of the surface obtained by induction hardening and the larger the residual compression stress, to enhance the fatigue life and the anti-slack capability.

4) The piece which widely used in electronic products is formed by stamping and automatic bending.

With the spring machines and equipment has become more mature, the spring processing lines will be more simplify, cost will be reduced.

1) Changing the spring outside diameter, pitch and diameter Suspension spring to achieve without molding processing. We usually use tapered steel bar winding working on CNC lathe machine since the development of the three transformers springs, but the yield and price are not good.

Now we get the tapered shape by through coiling spring machine in heated state and control the roll speed and pulling force, and use the waste heat to quench it.

2) Stable spring rod formed by low carbon boron-rolled steel welding.

3) Lever 45 steel with high purity, the high hardness of the surface obtained by induction hardening and the larger the residual compression stress, to enhance the fatigue life and the anti-slack capability.

4) The piece which widely used in electronic products is formed by stamping and automatic bending.

With the spring machines and equipment has become more mature, the spring processing lines will be more simplify, cost will be reduced.