Products

-

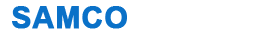

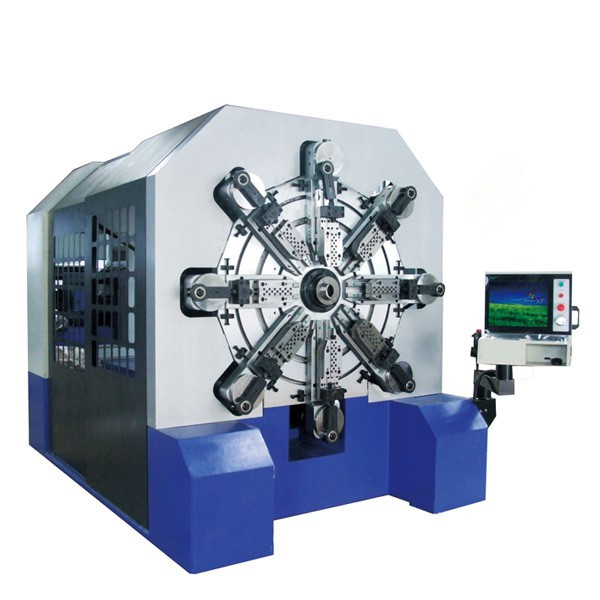

Revolutionary 12 axes spring & wire forming machines that allow spring manufacturers to massively produce a variety of springs with high speed and accuracy!

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

Special camless design equipped with SAMCO’s free arm technolgy that enables our series of spring machines to easily produce all kinds of difficult springs that is 30% or more efficient than traditional cam type spring former.

-

CNC8660 is 6-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

CNC8635 is six-axis compression spring machine, this CNC spring machine for making compression spring, oil seal spring ,battery spring, torsion machine, etc

-

SAMCO supply spring forming machine, CNC8335 is a 3 axis CNC spring machine, can make compression spring, tension spring, torsion spring, coiling spring and wire forms and etc

How to Protect the Surface of the Springs?

How to protect the surface of the spring? Spring surface is generally treated as black (blue), phosphate, electroplating, spray and so on.

In recent years, there was zinc chromate film DACROMET and it has protective layer with excellent corrosion resistance, corrosion resistance coatings 7-10 times, not the presence of hydrogen embrittlement plating process.

Dacromet surface of the product is silver white. Finish the main characteristics and uses corrosion-resistant properties of oxidized black, blue; commonly used to protect the general spring in the air for 3 months, plating protection for demanding general air medium protection three months to 2 years.

Phosphate processing capacity is higher than anti-embroidered oxidation treatment, the ability of high temperature 400 ℃ is to protect critical applications such as artillery guns parts, or as a pre-treatment of other non-metallic protective layer, paint, spray, electrophoresis paint and other anti-corrosion ability, wide applicability corrosion ability, especially in electrophoretic lacquer, currently used for automobile surface pre-treatment used special protective anti-rust oil in the refrigerator compressor springs no hydrogen embrittlement, simple process, environmental pollution production.